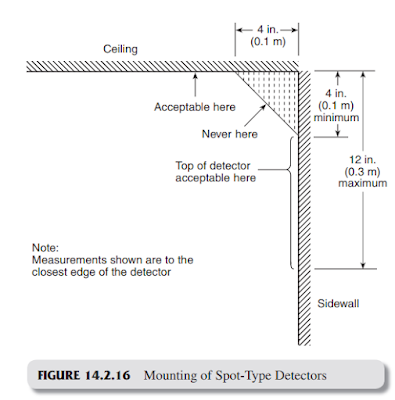

Spot-type detectors are usually installed on the ceiling, not less than 4 in. (0.1 m) from the wall. If their listing permits, they are also permitted to be installed on the wall, with their highest edge no less than 4 in. (0.1 m) and no more than 12 in. (0.3 m) from the ceiling (Figure 14.2.16).

Sunday, April 30, 2023

Fire alarm Detector Placement

FIRE ALARM SYSTEM BASICS

The basic components of each system are:

3. A secondary, or standby, power supply

4. One or more initiating device circuits or signaling line circuits to which manual fire alarm boxes, sprinkler waterflow alarm initiating devices, automatic fire detectors, and other fire alarm initiating devices are connected

5. One or more fire alarm notification appliance circuits to which audible and visible fire alarm notification appliances, such as bells, horns, stroboscopic lamps, and speakers, are connected

6. Many systems also have an off-premises connection to a central station, proprietary supervising station, remote supervising station, or public fire service communication center by means of an auxiliary fire alarm system

Secondary power supply for a fire alarm system is required to automatically supply the energy to the system within 30 seconds whenever the primary power supply is not capable

of providing the minimum voltage required for proper system operation.

Saturday, April 29, 2023

Design of Means of Egress

Friday, April 28, 2023

How many feed wide required for corridors in new hospital

the minimum width corridor required in hospital ?

As per NFPA 101 The width of an exit access should be at least sufficient for the number of persons it must accommodate. In some occupancies, the width of the access is governed by the character of activity in the occupancy. One example is a new hospital, where patients may be moved in beds or in gurneys. The corridors in the patient areas of the hospital must be 8 ft (2.4 m) wide to allow for a bed to be wheeled out of a room and turned 90º.

Wednesday, August 3, 2022

Ventilation of Restaurant-Type Cooking Equipment (CFPS)

Exhaust systems for restaurant equipment require careful design, because grease condenses in the interior of the ducts. Grease accumulations may be ignited by sparks from the cooking appliance or by a small fire on the cooking appliance caused by overheated cooking oil or fat in a deep-fat fryer or on a grill.

If the duct did not have a grease accumulation, cooking appliance fires could often be extinguished before causing appreciable damage.

- The system should be designed to minimize grease accumulations, with a minimum air velocity of 1500 ft/min (458 m/min) through any duct.

- Ducts should be arranged with ample clearance from combustible materials to minimize the danger of ignition, incase of fire in the duct.

- Ducts of substantial construction (not lighter than No. 16

Manufacturers Standard Gauge steel or No. 18 Manufacturers Standard Gauge stainless steel) should be used with all seams and joints having a liquid-tight, continuous weld. - Systems should be separated to ensure there is no connection with any other ventilating or exhaust system.

- Ducts should be led directly outside the building, without dips or traps, unless automatic grease removers are employed at the dips and traps.

- Openings should be provided for inspection and cleaning. Dampers should not be installed in any duct system, unless required as part of a grease extractor or extinguishing system.

Wednesday, May 11, 2022

DRY CHEMICAL EXTINGUISHING

OVERVIEW OF DRY CHEMICAL EXTINGUISHING AGENTS

Dry chemical extinguishing agents are commonly listed for use on Class B and Class C fires. Dry chemical extinguishing agents are not effective on Class D fires. Multipurpose dry chemical because they are listed for use on Class A, B, and C fires.

Extinguishing Properties

Smothering, cooling and radiation shielding contribute to the extinguishing efficiency of dry chemicals .but studies suggest that a chain-breaking reaction in the flame is the principal cause of extinguishment.

Cooling

Cooling action of the dry chemical cannot be substantiated as an important reason fot its ability to promptly extinguish fires. To be effective, any dry chemical must be heat sensitive and, as such, absorb heat in order to become chemically active.

Radiation Shielding.

Discharge of dry chemical produces a cloud of powder between the flame and the fuel; this cloud shields the fuel from some of the heat radiated by the flame.

Smothering Action

For special applications, such as kitchen range, hood, duct and fryer fire protection, the extinguishing mechanism for dry chemical is based on the process of saponification. Saponification is the process of chemically converting the fatty acid contained in the cooking medium to soap, or foam, and it accomplishes extinguishment by forming a surface coating that smoothers the fire.

Chain-Breaking Reaction.

The discharge of dry chemical into the flames prevents reactive particles from coming together and continuing the combustion chain reaction. The explanation is referred to as the chain-breaking mechanism of extinguishment.

Fixed systems are of two types:

- Total Flooding

- Hand Hose line/ Local Application

- Due to the rapidity with which dry chemical extinguishes flame, dry chemical is used on surface fires involving ordinary combustible materials (Class A Fires).

- There are several areas in the textile industry, notably opener-picker rooms and carding rooms in cotton mills, where regular dry chemical has been used effectively.

- Multipurpose dry chemicals becomes sticky when heated, it is not recommended for textile card rooms or other locations where removal of the residue from fine machine parts may be difficult.

- Dry chemicals should not be used in installations where relays and delicate electrical contacts are located, as the insulating properties of dry chemical might render such equipment inoperative.

- Dry chemical extinguishing systems can be used in those situations where quick extinguishment is desired and where re-ignition sources are not present.

- Regular dry chemical will not extinguish fires that penetrate beneath the surface or fires in materials that supply their own oxygen for combustion.

In total flooding applications, a predetermined amount of dry chemical is discharged through fixed piping and nozzles into an enclosed space or enclosure around the hazard.

Hand hose line systems containing regular or ordinary dry chemical have been used to a limited extent for quick spreading surface fires on ordinary combustible material.

Tuesday, May 10, 2022

Required Delivered Density

Required delivered density (RDD) is the minimum rate of water application that, if delivered to the top of the fuel package, is capable of providing early suppression.

NFPA 72 Understanding Supervisory Signal–Initiating Devices: Simplified Guide with Key Requirements"

Supervisory Signal–Initiating Devices Supervisory Signal–Initiating Devices This post explains the require...

-

Sprinkler Head Location There are two main criteria for site sprinkler heads. First, sprinklers should be located so as to be within t...

-

NFPA 72 Understanding Supervisory Signal–Initiating Devices: Simplified Guide with Key Requirements"Supervisory Signal–Initiating Devices Supervisory Signal–Initiating Devices This post explains the require...

-

Fire Pump Installation Quiz Fire Pump Installation Quiz 1. Among acceptable power supplies for fire pumps, which c...